Your Guide to Fabric Roofs & Walls Picking the Perfect Membrane for Your Project

January 28, 2026 By admin

Your Guide to Fabric Roofs & Walls: Picking the Perfect Membrane for Your Project

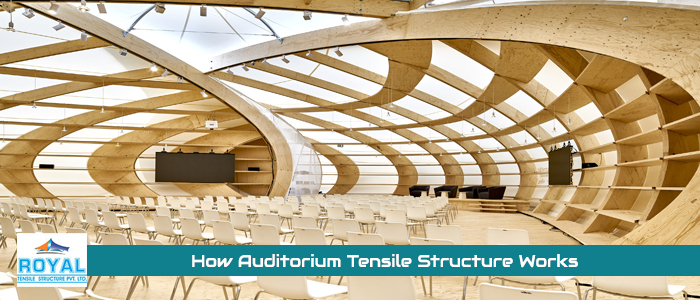

Your Guide to Fabric Roofs & Walls: Picking the Perfect Membrane for Your Project. Herein lies the magic of modern architecture being achieved due to tensile fabric structures. Not merely a fashionable look, tensile mesh structures represent an advanced engineering innovation of all sorts, including iconic cultural buildings as well as simple shelters.

However, with the various available materials, how do you select the appropriate material? This guide will be an 11-step journey of the main membrane types in order to help you select the ideal membrane for your next project.

The Reason Why a Tensile Structure is a Good Choice?

We can start with a recap of why things like tensile architecture are so attractive before we get into the materials:

- Freedom of Design: Design distinctive bodies of curves that one could hardly create using conventional materials.

- Durability: Good membranes can withstand extreme weather, mildew, and UV rays.

- Natural Lighting: Clothes made of translucent materials have made wonderful daylit rooms at lower costs of electricity.

- Portable and Low-Weight: The systems are reasonably lightweight and typically do not need a lot of structural support.

- Quickness of Construction: Prefabricated panels installed over the roof are much quicker than traditional roofing.

The Big Three: Membrane Material Tensile Common Materials

- PTFE (Polytetrafluoroethylene) Glass Fiber—The Everlasting Powerhouse. PTFE-coated fiberglass is the default option in permanent high-performance buildings and is often known by its iconic white color. What it is: A PTFE (non-stick polymer that is the same as Teflon) but composed of fiberglass cloth.Key Features: Inquisitive, Sturdiness: Shielded against fire and lacks chemical properties, and longevity of 30+ years.

- Cleaning: It is also self-cleaning, as dirt and grime can scarcely adhere to its non-stick surface, and the cleaning is mainly done by rain.

- Maturity Aesthetic: It begins tan and begins to fade to a permanent, bright white.

- Best Applied To: Permanent, large-scale undertakings such as stadium roofs, airport terminals, and large atria.

- ETFE (Ethylene Tetrafluoroethylene) Film—The New Wonder.ETFE is not woven but is a fluoropolymer film, which is transparent and mostly used in inflating cushions.

- Key Features: High Transparency: 95% of the light can be made to pass through, which offers the effect of being completely open and of being outdoors.

- Very Lightweight: Perhaps a hundred times lighter than glass or woven fabrics.

- Thermal Performance: The cushions, which are filled with air, present very good insulation.

- Best Use: Aquatic centers, botanical gardens, retail spaces, and any project where maximizing natural light is a priority.

- PVC (Polyvinyl Chloride) Polyester—The Multifunctional and Economical Alternative. The most common material, highly versatile and widely used, is the PVC-coated polyester, which is a good mix of performance and cost. What it is: A scrim made of polyester, coated using PVC, and overcoated with protective layers (such as PVDF or PVF).

- Key Features: Economical: Offers excellent durability at a reduced price in comparison to PTFE or ETFE.

- Flexibility & Versatility: Sold in many colors and degrees of translucency.

- Successful Past: A material that is known and has a normal life span of 15-20 years.

- Ideal: A huge selection of applications, which includes tensile car parking shelters, tensile walkway structure cover canopies, shade sails, and even very small commercial investments.

- On projects that require even further aesthetic appeal and dirt resistance, consider using PVC membranes with a 100% PVDF topcoat (such as the well-known Ferrari Precontraint series) or a tear-resistant PVF film (Tedlar).

Royal Tensile SPL is the company to consider when you want to find a partner who can comprehend this holistic material science for end product installation. We are a company that specializes in providing turnkey solutions for all tensile structure projects.

The knowledge of our craft is that the membrane you choose is custom-designed and produced to meet your exact needs, both aesthetically, environmentally, and economically, ensuring a structure that is both timeless and flawless.