The Role of Technology in Tensile Fabric Design and Construction

February 18, 2026 By admin

The Role of Technology in Tensile Fabric Design and Construction

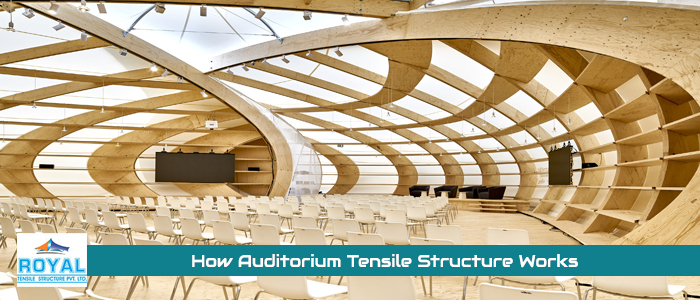

The modern architectural world honors tensile fabric structures because they represent lightweight designs that pair form with functionality while delivering visually stunning aesthetics. Architectural spaces receive new aesthetic perspectives through these methodologies that combine tensioned fabric membranes to create expansive, durable forms. These structures excel through structural ingenuity and artistic distinction since they appear in multiple facilities, including stadiums and airports, as well as pavilions and artistic installations. The foundation of this technological innovation conducts the entire design process and construction sequence.

Technological Advancements in Design

Advancements in technology have been instrumental in shaping the development of tensile fabric structures. The architectural field depends heavily on Computer-Aided Design (CAD) software combined with 3D modeling because these tools allow designers to produce precise visualizations of challenging geometric forms. The software provides architects with ways to try out novel shapes together with forms that previously seemed completely unworkable. Design procedures are improved through simulation software, which studies both structural durability together with wind-bearing capabilities and load distribution for making visually appealing yet functional designs. The Finite Element Analysis (FEA) tools allow designers to forecast how fabric membranes act under diverse settings, thus minimizing risks while optimizing materials.

Materials and Fabrication Techniques

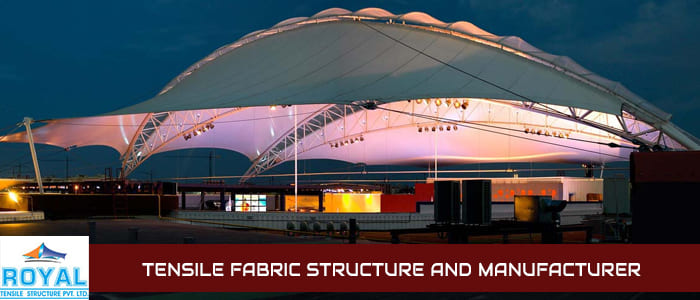

The development of technology resulted in substantial progress for tension fabric structure materials. Tensile fabric structures today utilize two advanced materials, PTFE-coated fiberglass and ETFE foils, to achieve greater durability alongside weather resistance and clarity. Modern tensile fabric structures receive advanced coatings that enhance their UV resistance as well as fire retardancy and self-cleaning ability. Renewables in design and computer-controlled fabrication techniques allow precise manufacturing of fabric panels through CNC (Computer Numerical Control) cutting and heat welding processes. The construction methods enhance product quality while decreasing waste production and reducing timelines, therefore making tensile fabric structures more efficient to build.

Sustainability and Technology

The architectural practice of sustainability continues to grow while tensile fabric buildings maintain an essential place. The advancement of technology enables better environmental friendliness in these building structures. Fabric membranes remain lightweight, so supporting structures become less necessary, and material usage and energy consumption decrease. Complex design software tools help architects maximize building openings to allow natural light access and ventilation, which cuts building energy costs effectively. Modern fabrics come with recyclability options, which support the establishment of circular economic systems. Every stage of design and construction now embraces sustainable practices, which makes tensile fabric structures the emerging sustainable choice for future projects.

Case Studies: Technology in Action

Several iconic projects showcase the successful integration of technology in tensile fabric structures. Modern lighting systems at the Allianz Arena in Munich, Germany, transform its ETFE panel façade into reactions of various colors. PTFE-coated fiberglass forms the covering for Denver International Airport’s roof to achieve a design that is both weight-reduction focused and resilient, along with being energy-efficient. These projects prove that technological advancements allow architects to improve design potential and support functional needs and environmental requirements.

Future Trends: What’s Next?

The future development of tensile fabric structures appears promising because emerging technologies will transform the field. Through the integration of AI technology, design processes would get automated while producing optimized structures at unprecedented speed. Fabric and construction automation will lead to increased precision and improved efficiency in the industry. Smart materials can transform into adaptive structures through environmental condition reactions, which produce instantaneous adjustments in their shape and properties. Building performance will advance through fabrics that alter their insulation properties or transparency according to temperature changes. The secondary development of existing technologies will enable architects and engineers to innovate through the ongoing evolution of tensile fabric structures.

Conclusion

Modern technology has revolutionized tensile fabric architectural design alongside construction methods by producing more efficient, sustainable, and innovative outcomes. The achievement of architectural wonders through tensile fabric structures heavily depends on technological advancements, which include advanced design methods together with high-performance materials and innovative fabrication approaches along with smart technologies. Future innovations in technology will release new capabilities that will position tensile fabric structures as top choices for modern architecture. The ongoing evolution of building design will be driven by technological developments because they enable architectural masterworks and green urban developments, which form the basis of human-experienced environments.